- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

Spring cone crusher

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Introduccin del producto Trituradora de cono estructura de marco principal, el eje horizontal, el cono mvil ,, excntrico, la pared de trituracin (cono fijo), la pared rota (cono dinmico), una parte del sistema de lubricacin, sistema hidruli

- +8613607653853

- 7*24 hours service hotline

Product Introduction

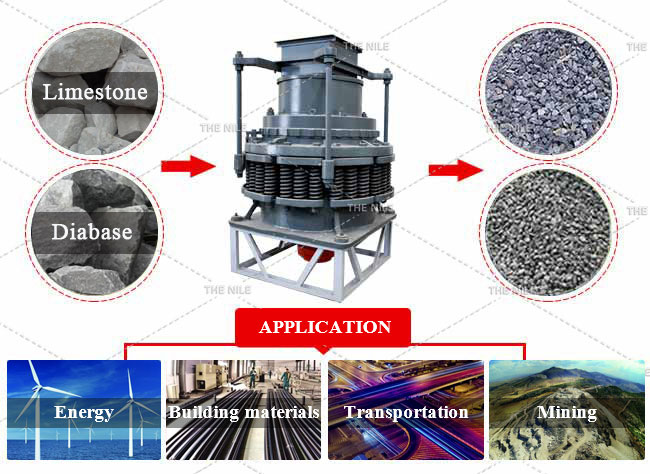

The structure of cone crusher consists of frame, horizontal axis, moving cone, eccentricity sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), lubrication system, hydraulic system, control system and so on. It is suitable for fine crushing and ultra fine crushing process for hard rock, slag, refractory and so on.

The structure of cone crusher consists of frame, horizontal axis, moving cone, eccentricity sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), lubrication system, hydraulic system, control system and so on. It is suitable for fine crushing and ultra fine crushing process for hard rock, slag, refractory and so on.

Working Principle

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates under the force of the eccentric shaft sleeve, and the section near the static cone becomes a broken cavity. The material is crushed by the extrusion and impact of the moving cone and the static cone. When the moving cone leaves the section, the material of the required particle size falls under the action of its own gravity and is discharged from the bottom of the cone.

In the working process of the cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates under the force of the eccentric shaft sleeve, and the section near the static cone becomes a broken cavity. The material is crushed by the extrusion and impact of the moving cone and the static cone. When the moving cone leaves the section, the material of the required particle size falls under the action of its own gravity and is discharged from the bottom of the cone.

Technical Data of the Spring cone crusher

| Model | Diameter of bottom end of conical crushing head (mm) | Max.Feed Size (mm) | Adjusting Range of output size (mm) | Capacity (t/h) | Power (kw) | Weight (t) | Dimensions (mm) |

| PY(B)600 | 600 | 65 | 12-25 | 15-25 | 30 | 5.5 | 1740×1225×1940 |

| PY(D)600 | 35 | 3-13 | 5-23 | 5.5 | 1740×1225×1940 | ||

| PY(B)900 | 900 | 115 | 15-50 | 50-90 | 55 | 11.2 | 1990×1640×2380 |

| PY(Z)900 | 60 | 5-20 | 20-65 | 11.2 | 1990×1640×2380 | ||

| PY (D) 900 | 40 | 3-13 | 15-50 | 11.3 | 1990×1640×2380 | ||

| PY (B) 1200 | 1200 | 145 | 20-50 | 110-168 | 110 | 24.7 | 2805×2300×2980 |

| PY (Z) 1200 | 100 | 8-26 | 42-135 | 25 | 2805×2300×2980 | ||

| PY (D) 1200 | 50 | 3-15 | 18-105 | 25.3 | 2805×2300×2980 | ||

| PY (B) 1750 | 1750 | 215 | 25-50 | 280-480 | 160 | 50.3 | 3610×2950×4185 |

| PY (Z) 1750 | 185 | 10-30 | 115-320 | 50.3 | 3610×2950×4185 | ||

| PY (D) 1750 | 85 | 5-15 | 75-230 | 50.2 | 3610×2950×4185 | ||

| PY (B) 2200 | 2200 | 300 | 30-60 | 590-1000 | 280 | 80 | 4790×3430×5080 |

| PY (Z) 2200 | 230 | 10-30 | 200-580 | 80 | 4790×3430×5080 | ||

| PY (D) 2200 | 100 | 5-16 | 120-340 | 81.4 | 4790×3430×5080 |