- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

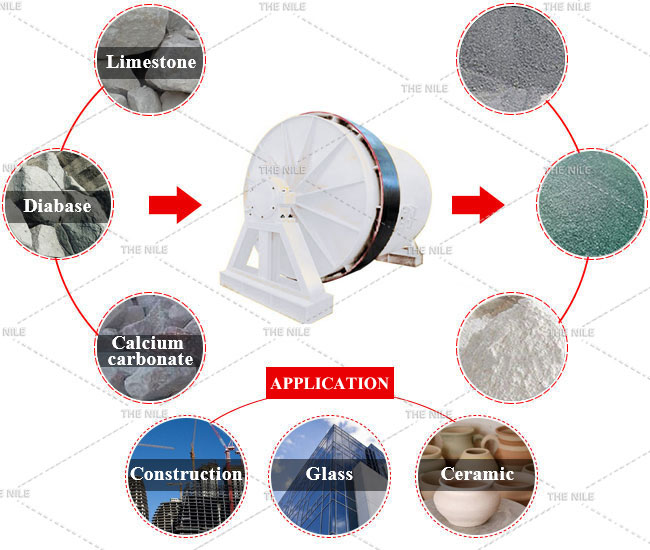

Ceramic ball mill

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Introduccin del producto ceramica molino de bolas es un ingeniero de cermica combinada con la ltima investigacin y desarrollo de nuevos molino de bolas , ahorro de energa tecnologa de molienda, molino de bolas de cermica se utiliza principa

- +8613607653853

- 7*24 hours service hotline

Ceramic ball mill is mainly used for mixing, grinding process dry or wet. Based on different production needs, it can adopt diffrent lining plates. Thickness of final products depend upon the grinding time. Motor startup with automatic voltage reducing to reduce the start current. Bearing adopts oil lubrication system, thus help bearing internal dirt cleaning and reduce the bearing attrition during normal operation. The Nile ceramic ball mill reduces replacement frequency of easily damaged parts at the most extent. lining plates 、steel balls are made of high chrome steel,which is very wear-resistiing and durable, brings a lot of advantages for ball mill’s maintenacne and working.

Advantages:

Ceramic ball mill has the characteristics of energy-saving, new structure, easy operation and stable performance, suited for traditional and special materials. We can choose suitable model and plates according to the proportion and hardness of materials of our customers.

Technical Data of the Ceramic ball mill

| Type |

Capacity (t/h) |

Cylinder speed (r/min) |

Motor power (kw) |

Weight (t) |

| TCQ910×1120 | 0.2 | 36 | 5.5-11 | 3.0 |

| TCQ1200×1400 | 0.5 | 32 | 11-18.5 | 3.8 |

| TCQ1500×1800 | 1.0 | 28 | 15-22 | 4.5 |

| TCQ1800×2100 | 1.5 | 26 | 18.5-30 | 6.0 |

| TCQ2100×2100 | 2.5 | 22 | 22-37 | 7.4 |

| TCQ2200×2400 | 3.0 | 20 | 28-45 | 8.2 |

| TCQ2500×2900 | 5.0 | 16 | 37-55 | 9.3 |

| TCQ2800×3700 | 8.0 | 14.5 | 55-75 | 12.5 |

| TCQ3000×3700 | 10 | 14 | 75-90 | 18.6 |