- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

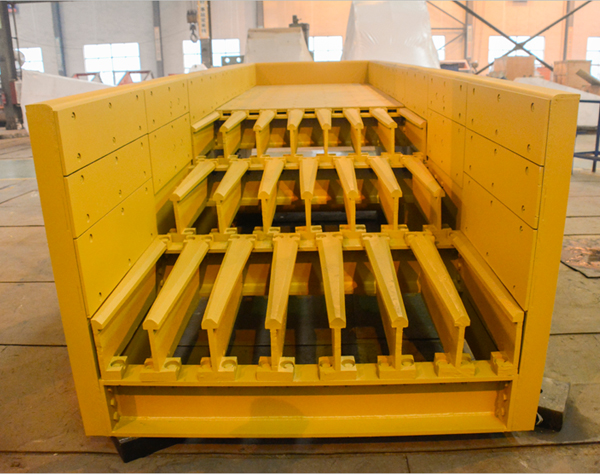

GZD vibrating feeder

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Product Introduction The vibrating feeder is used in the production process, it can send the massive and granular materials from the storage bunker into the receiver bin equably, regularly and continuously. It can feed the crushing machiner

- +8613607653853

- 7*24 hours service hotline

Product Introduction

The vibrating feeder is used in the production process, it can send the massive and granular materials from the storage bunker into the receiver bin equably, regularly and continuously. It can feed the crushing machinery continuously and uniformly, and conduct coarse screening on the materials in the sand production line. It is widely used in metallurgical, coal mine, mineral processing, building materials, chemical, abrasive and other industries of crushing, screening equipment.

The vibrating feeder is used in the production process, it can send the massive and granular materials from the storage bunker into the receiver bin equably, regularly and continuously. It can feed the crushing machinery continuously and uniformly, and conduct coarse screening on the materials in the sand production line. It is widely used in metallurgical, coal mine, mineral processing, building materials, chemical, abrasive and other industries of crushing, screening equipment.

Working Principle

The vibration feeder is the motion of the centrifugal force by rotating the eccentric block in the vibrator, so that the moving parts such as the box and the vibrator can be forced into a continuous circle or approximate circular motion. The vibrating feeder is composed of feeding trough body, exciter, spring support and transmission device. The vibration source for the vibration of the tank body is the exciter. The exciter is composed of two eccentric shafts (main and passive) and a gear pair. The motor drives the drive shaft through the V-belt, and then the gear on the drive shaft meshes with the drive shaft. The main and the drive shafts rotate in the opposite direction at the same time to make the tank body vibrate and make the material continuously flow to achieve the purpose of conveying the material.

The vibration feeder is the motion of the centrifugal force by rotating the eccentric block in the vibrator, so that the moving parts such as the box and the vibrator can be forced into a continuous circle or approximate circular motion. The vibrating feeder is composed of feeding trough body, exciter, spring support and transmission device. The vibration source for the vibration of the tank body is the exciter. The exciter is composed of two eccentric shafts (main and passive) and a gear pair. The motor drives the drive shaft through the V-belt, and then the gear on the drive shaft meshes with the drive shaft. The main and the drive shafts rotate in the opposite direction at the same time to make the tank body vibrate and make the material continuously flow to achieve the purpose of conveying the material.

Technical Data of the GZD vibrating feeder

| Model |

Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Cell dimension (mm) |

Overall Dimension (mm) |

| GZD-650*2300 | 300 | 80 | 1.1*2 | 2.8 | 650*2300 | 2300*1360*780 |

| GZD-750*2500 | 350 | 100 | 1.1*2 | 3.3 | 750*2500 | 2500*1460*780 |

| GZD-850*3000 | 400 | 120 | 3*2 | 3.6 | 850*3000 | 3110*1800*1600 |

| GZD-1000*3600 | 500 | 150 | 5.5*2 | 3.9 | 1000*3600 | 3850*1950*1630 |

| GZD-1100*4200 | 580 | 240 | 5.5*2 | 4.2 | 1100*4200 | 4400*2050*1660 |

| GZD-1100*4900 | 580 | 280 | 7.5*2 | 4.6 | 4900*1100 | 5200*2050*1700 |

| GZD-1300*4900 | 650 | 450 | 11*2 | 5.2 | 4900*1300 | 5200*2350*1750 |

| GZD-1500*5600 | 1050 | 450-800 | 12*2 | 7.5 | 1500*5600 | 5700*2000*1750 |