- Factory direct sales

- Quality Assurance

- Quick response

- Worry-free service

Wet pan mill

If you need help please contact us!

Factory direct sales:Yes

Delivery method:Sea/land

Introduccin del producto La mquina de molienda hmeda se llama mojadora de acuerdo con los diferentes modos de operacin, se divide en molino de oro, molino de amalgama de mercurio, molino de hierro, molino elctrico, de acuerdo con diferentes

- +8613607653853

- 7*24 hours service hotline

Product introduction

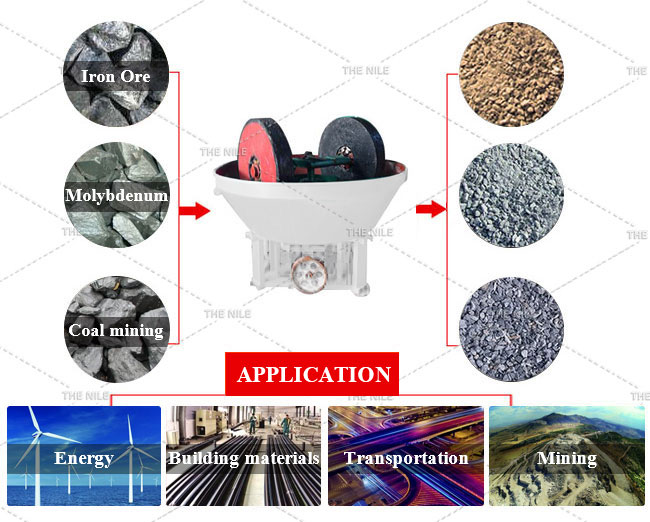

wet pan mill full name wet grinding machine, according to the different operating methods, divided into roller gold machine, mixed mercury grinding, grinding machine, electric milling.According to the different structure, divided into wheel mill, double gun, three gun grind.The wet-milling machine is based on the ancient stone mill, and has been developed through modernization.For a variety of ferrous metals, non-ferrous metals, non-metallic mineral grinding operations, as well as dilute precious metals, gold and silver grinding, selection, processing operations, is the majority of small and medium-sized concentrator, milling plant the best first grinding equipment.

wet pan mill full name wet grinding machine, according to the different operating methods, divided into roller gold machine, mixed mercury grinding, grinding machine, electric milling.According to the different structure, divided into wheel mill, double gun, three gun grind.The wet-milling machine is based on the ancient stone mill, and has been developed through modernization.For a variety of ferrous metals, non-ferrous metals, non-metallic mineral grinding operations, as well as dilute precious metals, gold and silver grinding, selection, processing operations, is the majority of small and medium-sized concentrator, milling plant the best first grinding equipment.

Working principle

The equipment is mainly composed of power plant, frame, water basin, roller wheel, ring and other components. The use of wheel-driven grinding working mode:First, the motor will drive to the reducer, driven by the reducer, through the large vertical shaft will be passed to the upper horizontal axis, and then installed at both ends of the horizontal rod transmission to the roller wheel, so that the roller to generate driving force,Do counterclockwise rotation along the horizontal axis, while working roller wheel can revolve around the large vertical shaft of the wet mill, and rotate around the center axis of the roller wheel, and the ring is fixed.

The equipment is mainly composed of power plant, frame, water basin, roller wheel, ring and other components. The use of wheel-driven grinding working mode:First, the motor will drive to the reducer, driven by the reducer, through the large vertical shaft will be passed to the upper horizontal axis, and then installed at both ends of the horizontal rod transmission to the roller wheel, so that the roller to generate driving force,Do counterclockwise rotation along the horizontal axis, while working roller wheel can revolve around the large vertical shaft of the wet mill, and rotate around the center axis of the roller wheel, and the ring is fixed.

Processing Details

1.CNC automatic cutting machine:Cutting surface of steel plate more smooth and steel plate size more accurate;

2.Rolling machine:better effect;the end parts are well connected;time&labor-saving;

3.Carbon dioxide arc welding:high temperature;the welding seam is smooth and the welding joint is durable;no slurry leakage from the joint;Electrochargeable liquid helps avoid iron liquid scattering around when welding and makes the outlook perfect;

1.CNC automatic cutting machine:Cutting surface of steel plate more smooth and steel plate size more accurate;

2.Rolling machine:better effect;the end parts are well connected;time&labor-saving;

3.Carbon dioxide arc welding:high temperature;the welding seam is smooth and the welding joint is durable;no slurry leakage from the joint;Electrochargeable liquid helps avoid iron liquid scattering around when welding and makes the outlook perfect;

Technical Data of the Wet pan mill

Model | Gauge (mm) | Feed Size (mm) | Engine power (kw) | Rotation speed (RPM) | Weight (t) |

1600A | 1600×400×200×500±20 | ≤25 | 6-30 | 20-22 | 14.5 |

1500A | 1500×350×200×460±20 | ≤25 | 6-22 | 20-22 | 13.3 |

1500B | 1500×350×150×460±20 | ≤25 | 6-22 | 20-22 | 12.3 |

1500C | 1500×300×150×420±20 | ≤25 | 6-22 | 20-22 | 11.3 |

1400A | 1400×250×150×350±20 | ≤25 | 6-18.5 | 16-18 | 8.5 |

1400B | 1400×250×150×350±20 | ≤25 | 6-18.5 | 21-23 | 8.5 |

1350A | 1350×250×150×350±20 | ≤25 | 6-18.5 | 16-18 | 8 |

1350B | 1350×250×150×350±20 | ≤25 | 6-18.5 | 21-23 | 8 |

1300A | 1300×250×150×350±20 | ≤25 | 6-15 | 16-18 | 7.5 |

1300B | 1300×200×150×350±20 | ≤25 | 4-15 | 21-23 | 7.5 |

1200A | 1200×220×80×270±20 | ≤25 | 6-7.5 | 17-19 | 5.5 |

1200B | 1200×200×80×250±20 | ≤25 | 6-7.5 | 23-25 | 5.5 |

1100A | 1100×200×80×250±20 | ≤25 | 6-7.5 | 17-19 | 5 |

1100B | 1100×180×80×250±20 | ≤25 | 4-7.5 | 23-25 | 5 |

1000 | 1000×200×80×250±20 | ≤25 | 4-7.5 | 13-15 | 4.5 |