News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

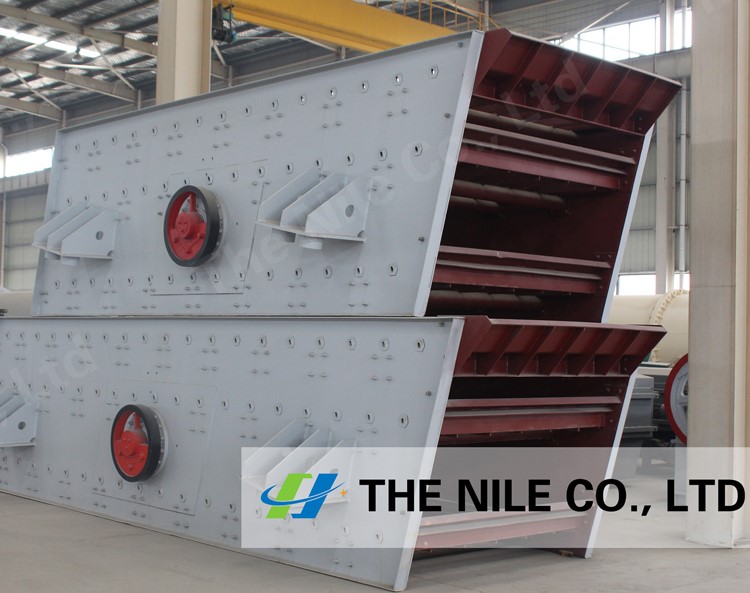

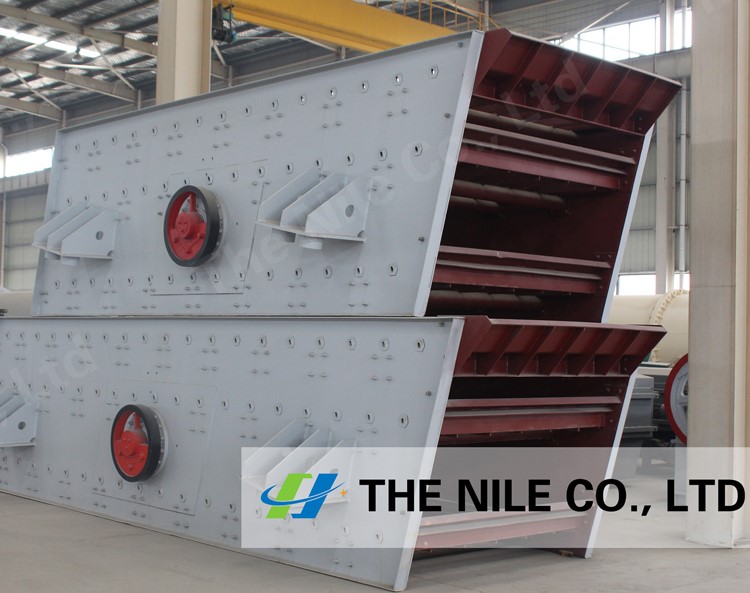

Multi-purpose high-efficiency multi-layer vibrating screen

Time:2019/01/25 News List

The vibration screen trajectory movement of the circular elliptical. It is a multi-layer, high-efficiency new type vibrating screen designed specifically for quarry screening stones. Widely used in mining, coal, smelting, building materials, refractories, light industry, chemical and other industries of product classification.

Working Principle

The round vibrating screen machine produced by the Nile mainly consists of a screen box, a screen, a vibrator, a vibration absorber spring device, a chassis and so on. The vibrator is installed on the side plate of the screen box, and the motor rotates through the triangle belt to produce the centrifugal inertial force and force the vibration of the screen box. The side plate of the screen machine is made of high quality steel plate, and the side plate is connected with the beam and the base of the exciter with high strength bolts or rivets of ring groove. The vibrator is mounted on the side plate of the screen box and rotated by the motor through the coupling to produce centrifugal inertia force, forcing the screen to vibrate.

Main features:

Main features:

1.Stable performance and high screening efficiency

The circular vibrating screen follows the structural design of the classic screening equipment, and its performance is fully guaranteed

2.A variety of screens to choose from

To meet the requirements of various classification operations after coarse crushing and medium crushing in the crushing process, we have configured a variety of screens for the circular vibrating screen. So that we can meet different production needs through simple screen replacement operations.

Working Principle

The round vibrating screen machine produced by the Nile mainly consists of a screen box, a screen, a vibrator, a vibration absorber spring device, a chassis and so on. The vibrator is installed on the side plate of the screen box, and the motor rotates through the triangle belt to produce the centrifugal inertial force and force the vibration of the screen box. The side plate of the screen machine is made of high quality steel plate, and the side plate is connected with the beam and the base of the exciter with high strength bolts or rivets of ring groove. The vibrator is mounted on the side plate of the screen box and rotated by the motor through the coupling to produce centrifugal inertia force, forcing the screen to vibrate.

1.Stable performance and high screening efficiency

The circular vibrating screen follows the structural design of the classic screening equipment, and its performance is fully guaranteed

2.A variety of screens to choose from

To meet the requirements of various classification operations after coarse crushing and medium crushing in the crushing process, we have configured a variety of screens for the circular vibrating screen. So that we can meet different production needs through simple screen replacement operations.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More