News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

How to choose the right crushing equipment based on mine raw materials?

Time:2019/11/27 News List

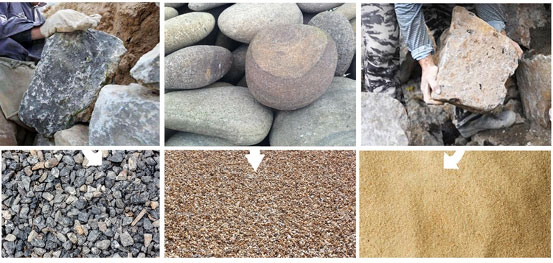

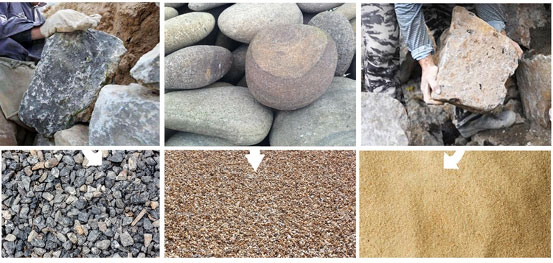

Sandstone aggregate is used as the basic material of engineering construction. Its commonly used raw materials are pebbles, granite, limestone, etc. Different raw materials require different crushing equipment.

In the process of processing, appropriate processing equipment should be selected according to different raw materials.

The raw materials can be divided into two types according to the hardness: hard stone and soft stone.

Hard stone: cobblestone, granite, basalt, etc.

Hardness: above 150Mpa

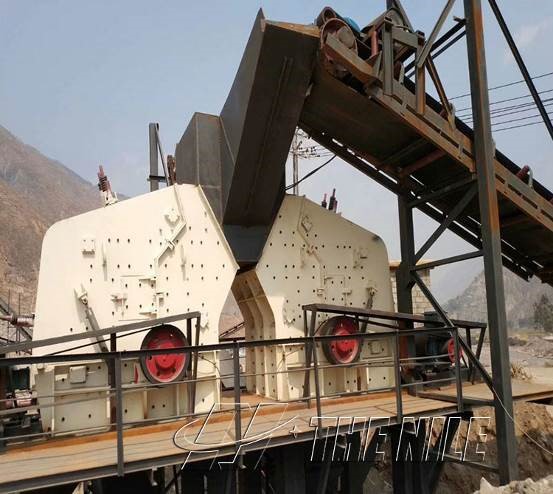

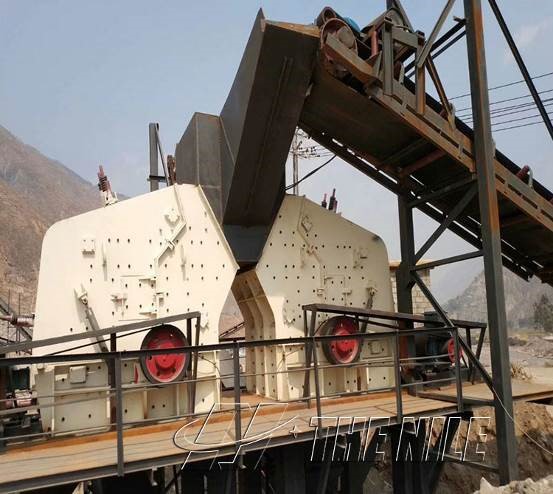

Treatment method: Jaw crusher and cone crusher are usually used for the crushing equipment. The impact crusher can be used for shaping according to the requirements of the finished product, and then the auxiliary equipment vibrating screen is used for sorting to sort the crushed materials into individual Specifications of the finished aggregate.

Soft stone: limestone, sandstone, etc.

Hardness below 150Mpa

Hardness below 150Mpa

Treatment method: For the crushing equipment, jaw crusher, impact crusher, and hammer crusher can be considered, and an impact crusher can also be used in accordance with the needs. Important note: The hardness of limestone varies greatly depending on its silicon content. If limestone with a high silicon content is crushed, a cone crusher is required.

There are many ways to choose sandstone aggregate processing equipment and process design. How to choose and match specific requirements requires comprehensive consideration of many factors such as the hardness, looseness, mud content, finished product requirements of different raw materials. When The Nile Machinery Co., Ltd. configures the solution for the customer, it will go to the site to configure the appropriate equipment according to the situation of the material, so that you have no worries in the production process.

There are many ways to choose sandstone aggregate processing equipment and process design. How to choose and match specific requirements requires comprehensive consideration of many factors such as the hardness, looseness, mud content, finished product requirements of different raw materials. When The Nile Machinery Co., Ltd. configures the solution for the customer, it will go to the site to configure the appropriate equipment according to the situation of the material, so that you have no worries in the production process.

The raw materials can be divided into two types according to the hardness: hard stone and soft stone.

Hard stone: cobblestone, granite, basalt, etc.

Hardness: above 150Mpa

Treatment method: Jaw crusher and cone crusher are usually used for the crushing equipment. The impact crusher can be used for shaping according to the requirements of the finished product, and then the auxiliary equipment vibrating screen is used for sorting to sort the crushed materials into individual Specifications of the finished aggregate.

Soft stone: limestone, sandstone, etc.

Treatment method: For the crushing equipment, jaw crusher, impact crusher, and hammer crusher can be considered, and an impact crusher can also be used in accordance with the needs. Important note: The hardness of limestone varies greatly depending on its silicon content. If limestone with a high silicon content is crushed, a cone crusher is required.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More