News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Installation and maintenance of wet pan mill

Time:2019/12/06 News List

The maintenance of wet pan mill is an extremely important recurring task. It should be closely coordinated with wet pan mills operation and maintenance.

Installation test:

Installation test:

1. The equipment should be installed on a horizontal concrete foundation and fixed with anchor bolts.

2. When installing, pay attention to the main body and the vertical.

3. After installation, check whether the bolts in all parts are loose and whether the main engine compartment door is tight.

4. Configure the power cord and control switch according to the power of the device.

5. After the inspection is completed, carry out a no-load test run, and the test run can start production.

Maintenance of the machine:

Maintenance of the machine:

1. The shaft bears the full load of the negative machine, so good lubrication has a great relationship with bearing life. It directly affects the service life and operating rate of the machine. Therefore, the injected lubricant must be clean and the seal must be good. Main oiling points (1) rotating bearings (2) roller bearings (3) all gears (4) movable bearings, sliding planes.

2. The newly installed wheels are prone to loosening and must be checked frequently.

3. Pay attention to whether the parts of the machine work normally.

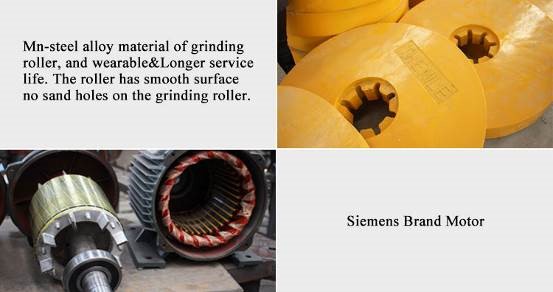

4. Pay attention to check the wear degree of the easy-wear parts, and pay attention to replacing the worn parts at any time.

4. Pay attention to check the wear degree of the easy-wear parts, and pay attention to replacing the worn parts at any time.

5. For the plane of the chassis of the mobile device, dust and other materials should be removed to prevent the movable bearing from moving on the chassis when the machine encounters unbreakable materials, resulting in serious accidents.

6. Bearing oil temperature rises, stop immediately and check the cause.

7. If there is an impact sound when the gear is turned, it should be stopped immediately for inspection and eliminated.

1. The equipment should be installed on a horizontal concrete foundation and fixed with anchor bolts.

2. When installing, pay attention to the main body and the vertical.

3. After installation, check whether the bolts in all parts are loose and whether the main engine compartment door is tight.

4. Configure the power cord and control switch according to the power of the device.

5. After the inspection is completed, carry out a no-load test run, and the test run can start production.

1. The shaft bears the full load of the negative machine, so good lubrication has a great relationship with bearing life. It directly affects the service life and operating rate of the machine. Therefore, the injected lubricant must be clean and the seal must be good. Main oiling points (1) rotating bearings (2) roller bearings (3) all gears (4) movable bearings, sliding planes.

2. The newly installed wheels are prone to loosening and must be checked frequently.

3. Pay attention to whether the parts of the machine work normally.

5. For the plane of the chassis of the mobile device, dust and other materials should be removed to prevent the movable bearing from moving on the chassis when the machine encounters unbreakable materials, resulting in serious accidents.

6. Bearing oil temperature rises, stop immediately and check the cause.

7. If there is an impact sound when the gear is turned, it should be stopped immediately for inspection and eliminated.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More