News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Common Coal Crushers

Time:2020/01/14 News List

As one of the main energy sources, the processing and utilization of coal can affect the realization of its economic value. For its initial processing, it is generally inseparable from the crushing equipment. There are many types of crushers that can crush coal.

Common Classification of Coal Crushers

Common Classification of Coal Crushers

Generally, the type of crusher to be used is decided according to the granularity required. Coal crushing can be divided into squeeze coal crusher, impact coal crusher and shredder coal crusher according to the main force of the crushed material:

1.Extrusion coal crusher

1.Extrusion coal crusher

It mainly includes jaw crusher, rotary crusher, cone crusher, roller crusher and so on.

Such crusher materials are crushed by crushing, splitting and bending between the fixed tooth plate and the movable tooth plate of the crusher.

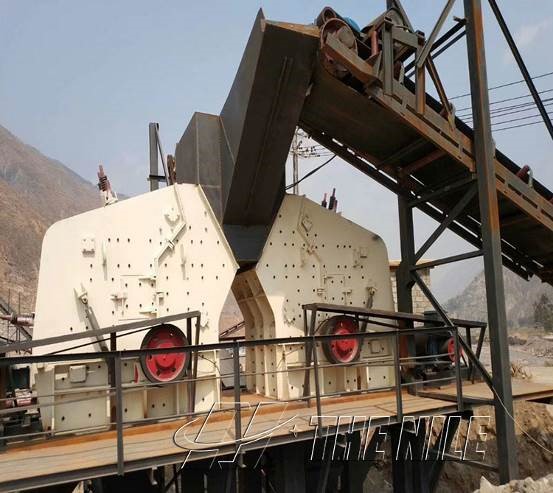

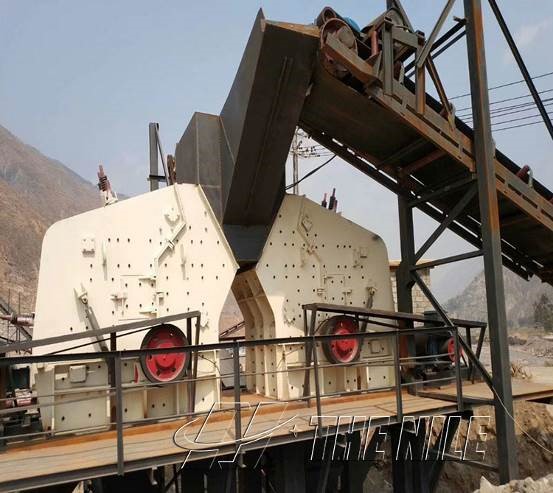

2.Impact coal crusher

2.Impact coal crusher

It mainly includes impact crusher and ring hammer crusher.

This type of crusher hits the material with a hammer that moves at a high speed. After each impact, the material accelerates to the impact plate. The repeated effects of impact and counter-impact and the mutual crushing impact of the impacted object in the crushing cavity. The impact blade and the impact plate are sheared to achieve the purpose of crushing materials.

3.Shredder coal crusher

3.Shredder coal crusher

Double-toothed roller classifier, WMG-type roller crusher, double-toothed roller crusher are all shear-type coal crushers. This type of crusher makes full use of the strength characteristics of coke, etc., and achieves the purpose of crushing by shearing, stretching, bending, puncturing, breaking, splitting, etc. of the material.

Generally, the type of crusher to be used is decided according to the granularity required. Coal crushing can be divided into squeeze coal crusher, impact coal crusher and shredder coal crusher according to the main force of the crushed material:

It mainly includes jaw crusher, rotary crusher, cone crusher, roller crusher and so on.

Such crusher materials are crushed by crushing, splitting and bending between the fixed tooth plate and the movable tooth plate of the crusher.

It mainly includes impact crusher and ring hammer crusher.

This type of crusher hits the material with a hammer that moves at a high speed. After each impact, the material accelerates to the impact plate. The repeated effects of impact and counter-impact and the mutual crushing impact of the impacted object in the crushing cavity. The impact blade and the impact plate are sheared to achieve the purpose of crushing materials.

Double-toothed roller classifier, WMG-type roller crusher, double-toothed roller crusher are all shear-type coal crushers. This type of crusher makes full use of the strength characteristics of coke, etc., and achieves the purpose of crushing by shearing, stretching, bending, puncturing, breaking, splitting, etc. of the material.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More