News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

What is the Difference Between a Jaw Crusher and an Impact Crusher?

Time:2020/08/02 News List

The common crushing production line of mine generally includes three links: coarse crushing, fine crushing and sand making. Reasonable equipment configuration plays a key role in upgrading the production and improving the grain shape of the whole line.The equipment which belonging to secondary crushing are cone crusher and impact crusher, since both are secondary crushing equipment, what is the difference between them?

1. Working principle

1. Working principle

Cone crusher is mainly composed of fixed cone, moving cone, crushing wall, transmission axis and frame etc. According to the principle of laminated crushing, the materials are continuously crushed in the crushing chamber by squeezing into each other.

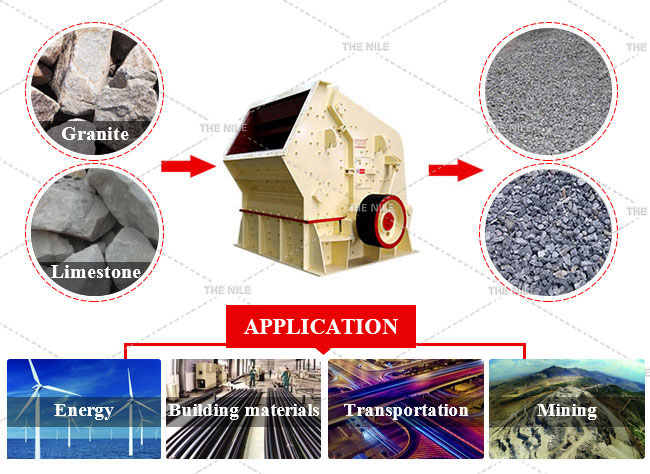

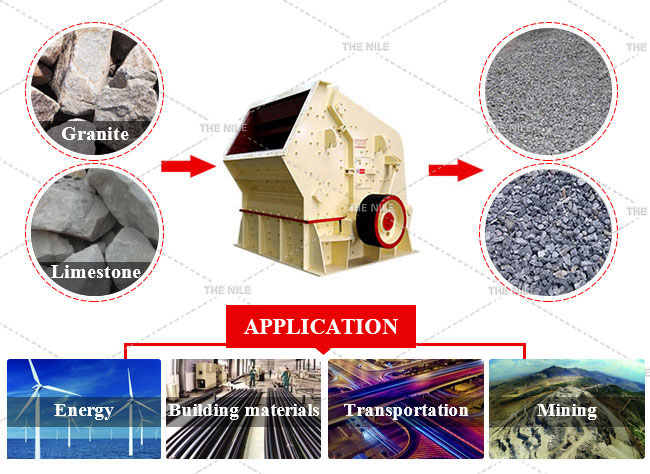

The impact crusher is mainly composed of rotor, plate hammer, impact plate and lining plate etc. The crushing method about that is impact crushing. The material is broken under the continuous impact of the plate hammer and impact plate until it is crushed into the appropriate size and then discharged from the outlet.

2. Applicable materials

Cone crusher is widely used in metallurgy, building materials, road and bridge paving and other industries. It is suitable for crushing materials with medium or above hardness, such as granite, basalt, tuff, river pebble, etc.

Impact crusher is widely used in construction waste crushing, sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar and other scenes. It is suitable for all kinds of low toughness and brittle stones and ores with medium soft hardness and below, such as limestone, limestone, bricks and concrete etc.

3. Processing capacity

Compared with impact crusher, cone crusher has larger processing capacity and higher crushing efficiency,which is more suitable for large-scale and high-yield production line operation.

4. Finished grain shape

4. Finished grain shape

There are more needle flakes in the cone crusher, but the grain produced by impact crusher has better shape and fewer edge.

5. Investment cost

The cone crusher is more expensive than impact crusher, but its wearing parts have a longer durability and lower maintenance costs.

Cone crusher and impact crusher have their own characteristics. We need to choose according to materials, output, investment funds and so on. If the requirements for finished product grain shape are high, it is recommended to choose impact crusher. If large output is required, it is recommended to select cone crusher, because the output of cone crusher is large, energy consumption is low, and the maintenance cost is low.

As the manufacturer of crushing plants, Nile Machinery has more than 30 years of production experience and supply jaw crusher, hammer crusher, composite crusher, and other equipment besides the cone crusher and impact crusher. Welcome to consult the quotation, if you have the plan for buying crushers.

Cone crusher is mainly composed of fixed cone, moving cone, crushing wall, transmission axis and frame etc. According to the principle of laminated crushing, the materials are continuously crushed in the crushing chamber by squeezing into each other.

The impact crusher is mainly composed of rotor, plate hammer, impact plate and lining plate etc. The crushing method about that is impact crushing. The material is broken under the continuous impact of the plate hammer and impact plate until it is crushed into the appropriate size and then discharged from the outlet.

2. Applicable materials

Cone crusher is widely used in metallurgy, building materials, road and bridge paving and other industries. It is suitable for crushing materials with medium or above hardness, such as granite, basalt, tuff, river pebble, etc.

Impact crusher is widely used in construction waste crushing, sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar and other scenes. It is suitable for all kinds of low toughness and brittle stones and ores with medium soft hardness and below, such as limestone, limestone, bricks and concrete etc.

3. Processing capacity

Compared with impact crusher, cone crusher has larger processing capacity and higher crushing efficiency,which is more suitable for large-scale and high-yield production line operation.

There are more needle flakes in the cone crusher, but the grain produced by impact crusher has better shape and fewer edge.

5. Investment cost

The cone crusher is more expensive than impact crusher, but its wearing parts have a longer durability and lower maintenance costs.

Cone crusher and impact crusher have their own characteristics. We need to choose according to materials, output, investment funds and so on. If the requirements for finished product grain shape are high, it is recommended to choose impact crusher. If large output is required, it is recommended to select cone crusher, because the output of cone crusher is large, energy consumption is low, and the maintenance cost is low.

As the manufacturer of crushing plants, Nile Machinery has more than 30 years of production experience and supply jaw crusher, hammer crusher, composite crusher, and other equipment besides the cone crusher and impact crusher. Welcome to consult the quotation, if you have the plan for buying crushers.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More