News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

The Difference Between Jaw Crusher and Impact Crusher

Time:2020/09/07 News List

Jaw crusher and impact crusher are commonly used equipment in crushing site, but there are great differences between them in practical application.

Jaw crusher

1. Different Structures

Jaw crusher machine is mainly composed of fixed jaw plate, movable jaw plate, frame, upper and lower guard plate, adjusting seat, moving jaw rod, etc.

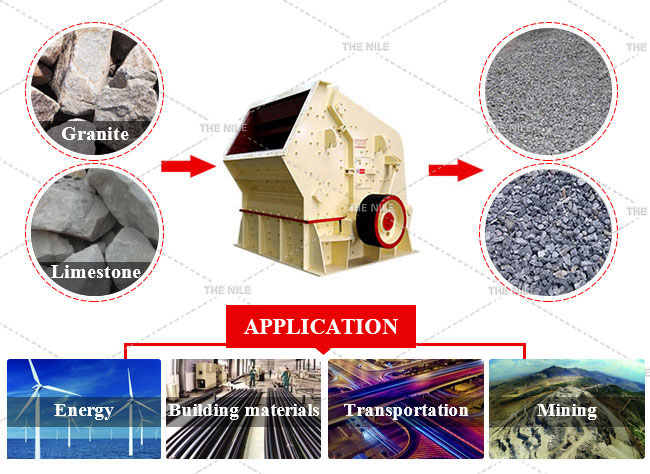

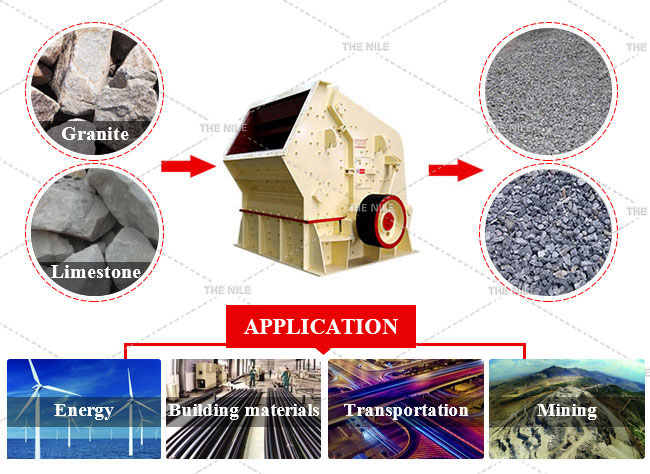

The main components of impact crusher are spring, front impact frame, rear impact frame, impact lining plate, square steel, impact lining plate bolt, cover turning device, main shaft, plate hammer, rotor frame, lining plate, locking block, pressing block, etc.

2. Different Working Principles

The working mode of jaw crusher is extrusion crushing. The material is crushed in the crushing cavity composed of moving jaw and fixed jaw. The impact crusher adopts impact crushing principle, and the material is repeatedly impacted and broken between rotor (plate hammer) and impact plate.

3. Different Hardness and Particle Size of Materials

Jaw crusher can crush various large soft and hard materials with compressive strength between 300-350mpa, while impact crusher is suitable for crushing low toughness and brittleness materials with a compressive strength of less than 350Mpa, such as limestone, quartz, dolomite, etc. If the material is hard, it will cause great damage to the wearing parts and shorten the service life of stone crusher. The impact crusher is mostly used to process some small and medium-sized materials. Usually, the feed size should be smaller than the size of the feed inlet, and better to be less than 500mm. The allowable feed size range of impact crusher machine is not as wide as the jaw crusher plant.

Impact crusher

4. Different Position in the Production Line

In the production lines of crushing, sand making, ore dressing, etc., stone jaw crusher is a commonly used primary crushing equipment for coarse crushing, while impact crushing plant is commonly used as secondary or tertiary crushing equipment for medium or fine crushing.

5. Different Discharge Particle Types

After jaw crusher extrusion treatment, the material particle size is not ideal, and the content of needle pieces is more. The material particle of the impact crushing plant has better shape and less edge angle, which is even better than that of cone crusher.

According to the difference between jaw crusher and impact crusher, how to choose a suitable crusher? If the material is relatively large and high hardness stone such as cobble and granite, it is recommended to use jaw crusher. If the particle size of material is not large and there are strict requirements for finished products, such as limestone, bluestone and other soft stone crushing, it is recommended to use impact crusher to have better effect. Of course, it is better to use the jaw crusher and the impact crusher together to ensure that all the large stones can enter the crusher smoothly for crushing treatment, and also can ensure the effect of finished products.

Jaw crusher

Jaw crusher machine is mainly composed of fixed jaw plate, movable jaw plate, frame, upper and lower guard plate, adjusting seat, moving jaw rod, etc.

The main components of impact crusher are spring, front impact frame, rear impact frame, impact lining plate, square steel, impact lining plate bolt, cover turning device, main shaft, plate hammer, rotor frame, lining plate, locking block, pressing block, etc.

2. Different Working Principles

The working mode of jaw crusher is extrusion crushing. The material is crushed in the crushing cavity composed of moving jaw and fixed jaw. The impact crusher adopts impact crushing principle, and the material is repeatedly impacted and broken between rotor (plate hammer) and impact plate.

3. Different Hardness and Particle Size of Materials

Jaw crusher can crush various large soft and hard materials with compressive strength between 300-350mpa, while impact crusher is suitable for crushing low toughness and brittleness materials with a compressive strength of less than 350Mpa, such as limestone, quartz, dolomite, etc. If the material is hard, it will cause great damage to the wearing parts and shorten the service life of stone crusher. The impact crusher is mostly used to process some small and medium-sized materials. Usually, the feed size should be smaller than the size of the feed inlet, and better to be less than 500mm. The allowable feed size range of impact crusher machine is not as wide as the jaw crusher plant.

Impact crusher

In the production lines of crushing, sand making, ore dressing, etc., stone jaw crusher is a commonly used primary crushing equipment for coarse crushing, while impact crushing plant is commonly used as secondary or tertiary crushing equipment for medium or fine crushing.

5. Different Discharge Particle Types

After jaw crusher extrusion treatment, the material particle size is not ideal, and the content of needle pieces is more. The material particle of the impact crushing plant has better shape and less edge angle, which is even better than that of cone crusher.

According to the difference between jaw crusher and impact crusher, how to choose a suitable crusher? If the material is relatively large and high hardness stone such as cobble and granite, it is recommended to use jaw crusher. If the particle size of material is not large and there are strict requirements for finished products, such as limestone, bluestone and other soft stone crushing, it is recommended to use impact crusher to have better effect. Of course, it is better to use the jaw crusher and the impact crusher together to ensure that all the large stones can enter the crusher smoothly for crushing treatment, and also can ensure the effect of finished products.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More