News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Comparison of Production Performance Between Continuous Ball Mill and Intermittent Ball Mill

Time:2020/12/03 News List

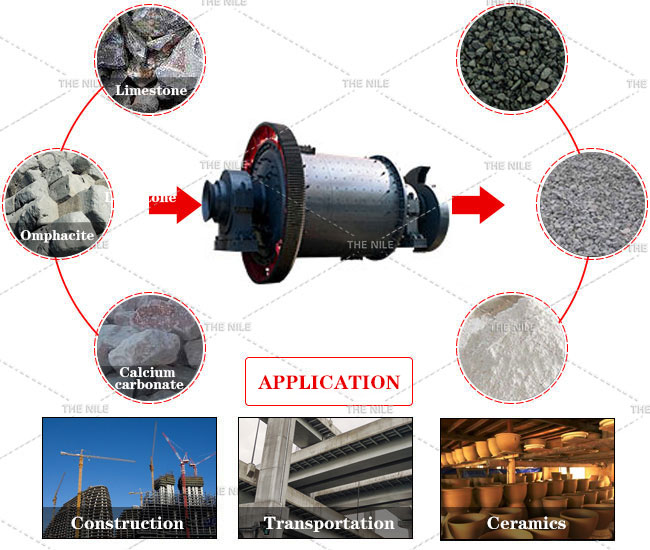

Ball mill belongs to mineral processing equipment. Its main function is to use steel balls as grinding media to grind materials in various industries such as metals, new building materials, refractory materials, and glass ceramics. According to different working principles, mineral ball mills can be divided into continuous ball mills and intermittent ball mills. In addition to the differences in the working principle, what are the differences in production performance between the two?

Performance advantages of continuous ball mill machine

1. Low energy consumption. The continuous industrial ball mill has higher requirements on the temperature of the cylinder. Such temperature conditions and the dynamic slurry discharge mode make the viscosity of the material after grinding lower, reduce the water consumption and evaporation of the material so that the power consumption is low.

2. Continuous operation makes the control system used more advanced and highly automated.

3. Production can be adjusted according to the state of the material, the grinding effect is better, the phenomenon of over-grinding is less, and the adaptability is stronger.

4. It can save the time of feeding and discharging slurry, and improve the production efficiency to a certain extent.

Performance advantages of intermittent ball mill grinding machine

1. Two bins for grinding. Coarse grinding and fine grinding of materials, and separate bin grinding, can improve the grinding accuracy and also help improve the quality of the finished product of the fine refining ball mill.

2. Convenient maintenance. The internal lining plate, steel ball, and other accessories of the two grinding bins are different. During maintenance, the wear conditions in the two grinding bins are different, which can be overhauled separately and very convenient.

3. More energy saving. Compared with traditional mining ore stone ball mills, it can save 40% - 50% power consumption. Through the pressurization effect of the power distribution circuit, the start-up time is reduced by 3-5 minutes, and the production and grinding efficiency are increased by more than 20%.

4. Suitable for mixing and grinding operations of ordinary and special materials.

5. The appropriate model, liner, and medium type can be selected according to factors such as the specific gravity, hardness of the material and the output of the ball mill stone grinder.

The above are the production advantages of continuous ball mills and intermittent ball mills. Users can choose suitable equipment according to the actual situation. Nile Machinery provides a wide range of ball mill equipment, with more classifications and complete models, and the output can also meet the user's production standards. Welcome users who need to consult and order online.

1. Low energy consumption. The continuous industrial ball mill has higher requirements on the temperature of the cylinder. Such temperature conditions and the dynamic slurry discharge mode make the viscosity of the material after grinding lower, reduce the water consumption and evaporation of the material so that the power consumption is low.

2. Continuous operation makes the control system used more advanced and highly automated.

3. Production can be adjusted according to the state of the material, the grinding effect is better, the phenomenon of over-grinding is less, and the adaptability is stronger.

4. It can save the time of feeding and discharging slurry, and improve the production efficiency to a certain extent.

Performance advantages of intermittent ball mill grinding machine

1. Two bins for grinding. Coarse grinding and fine grinding of materials, and separate bin grinding, can improve the grinding accuracy and also help improve the quality of the finished product of the fine refining ball mill.

2. Convenient maintenance. The internal lining plate, steel ball, and other accessories of the two grinding bins are different. During maintenance, the wear conditions in the two grinding bins are different, which can be overhauled separately and very convenient.

3. More energy saving. Compared with traditional mining ore stone ball mills, it can save 40% - 50% power consumption. Through the pressurization effect of the power distribution circuit, the start-up time is reduced by 3-5 minutes, and the production and grinding efficiency are increased by more than 20%.

4. Suitable for mixing and grinding operations of ordinary and special materials.

5. The appropriate model, liner, and medium type can be selected according to factors such as the specific gravity, hardness of the material and the output of the ball mill stone grinder.

The above are the production advantages of continuous ball mills and intermittent ball mills. Users can choose suitable equipment according to the actual situation. Nile Machinery provides a wide range of ball mill equipment, with more classifications and complete models, and the output can also meet the user's production standards. Welcome users who need to consult and order online.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More