News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Introduction to the working principle of impact crusher

Time:2021/08/03 News List

The impact crusher is also called the impact stone crusher, which is mainly used in building materials, transportation, energy, cement, mining, chemical and other industries. It is widely used in highway construction, water conservancy engineering, construction gravel, machine-made sand processing and other fields. It is very suitable for crushing various soft and medium-hard ores.

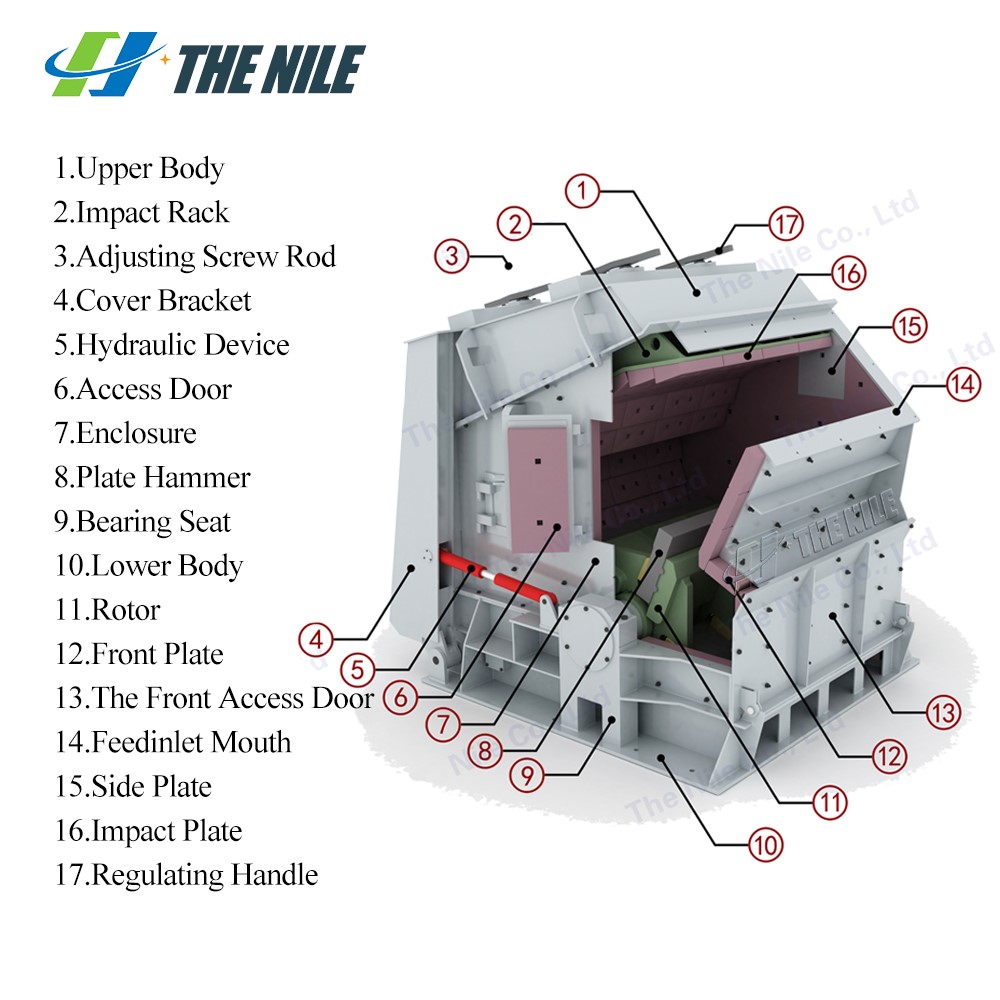

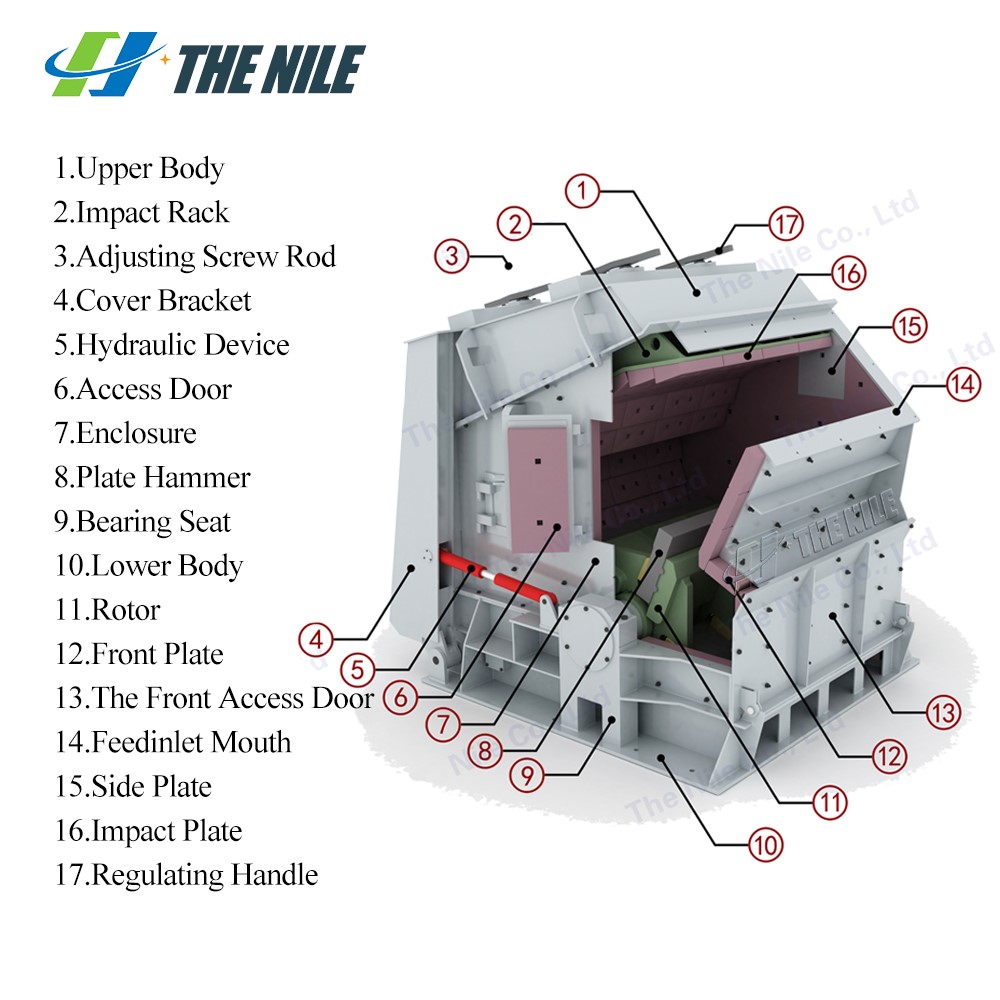

The stone impact crusher is mainly composed of rotor, impact frame, frame and rotating parts.Hammer, liner, impact plate, spring and bearing are the vulnerable parts of impact crusher machine. It is necessary to pay attention to routine maintenance and replacement at any time to prevent work interruption.

The stone impact crusher is mainly composed of rotor, impact frame, frame and rotating parts.Hammer, liner, impact plate, spring and bearing are the vulnerable parts of impact crusher machine. It is necessary to pay attention to routine maintenance and replacement at any time to prevent work interruption.

Note: Impact crusher equipment can crush ores and rocks whose maximum feed size is generally not more than 400mm and compressive strength not more than 150Mpa; it is not suitable for crushing ores or viscous materials with surface moisture greater than 8-10%.

The principle of impact crusher

When the material enters the impact area of the blow hammer, the high-speed impact of the blow hammer causes the broken objects to be continuously thrown to the counterattack device installed above the rotor, and then bounce back from the counterattack liner of the impact crushing machine to the impact area of the blower.

The crushing is repeated in the crushing cavity until the material is crushed to the required size and discharged from the bottom discharge port of the counter-attack breaker.

High-quality quality comes from top suppliers. The impact crusher stone machine produced by Nile River Company is of good quality, excellent price and simple operation. Welcome to contact us and visit our factory!

High-quality quality comes from top suppliers. The impact crusher stone machine produced by Nile River Company is of good quality, excellent price and simple operation. Welcome to contact us and visit our factory!

Note: Impact crusher equipment can crush ores and rocks whose maximum feed size is generally not more than 400mm and compressive strength not more than 150Mpa; it is not suitable for crushing ores or viscous materials with surface moisture greater than 8-10%.

The principle of impact crusher

When the material enters the impact area of the blow hammer, the high-speed impact of the blow hammer causes the broken objects to be continuously thrown to the counterattack device installed above the rotor, and then bounce back from the counterattack liner of the impact crushing machine to the impact area of the blower.

The crushing is repeated in the crushing cavity until the material is crushed to the required size and discharged from the bottom discharge port of the counter-attack breaker.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More