News Center

you can keep abreast of the latest news of NILE and the hot information of the industry.

Four tips teach you how to choose the right vibrating screen equipment

Time:2021/08/11 News List

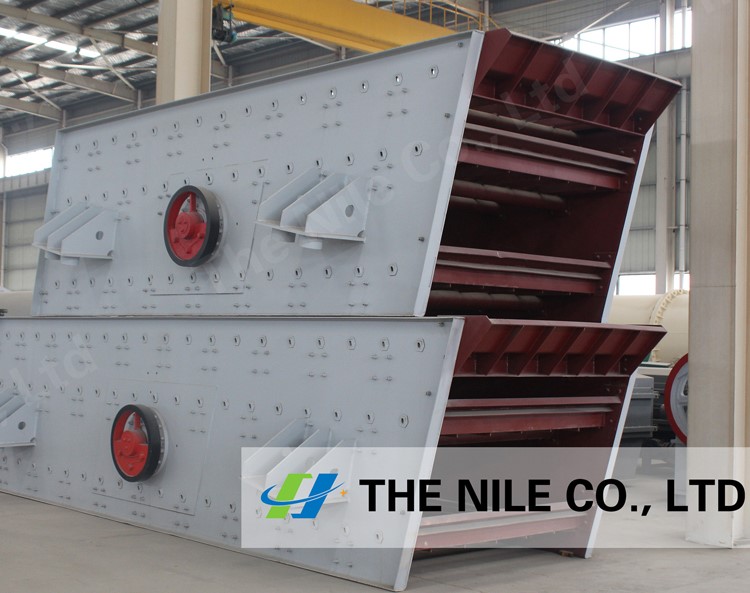

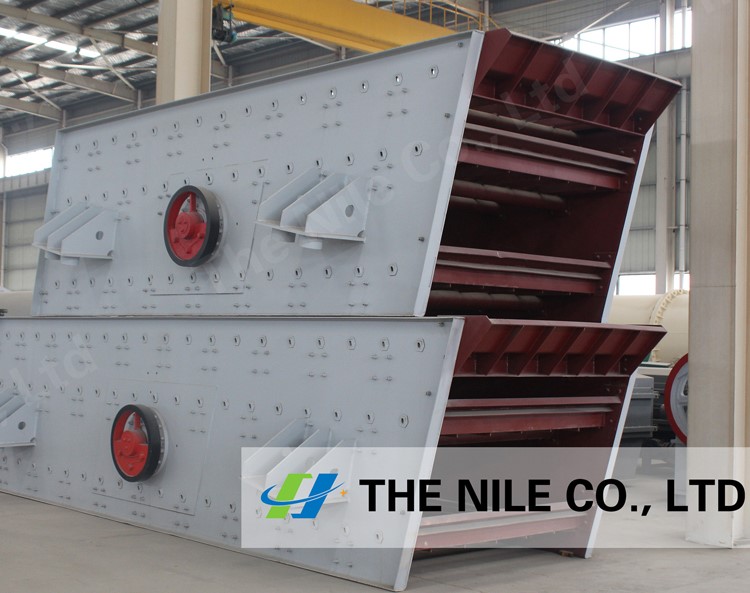

There are various types of vibrating screen equipment. Among them, the circular vibrating screen is a common vibrating screen equipment. The circular vibrating screen machine is a multi-layer, high-efficiency new type of vibrating screen, which is widely used for product classification in the mining, building materials, transportation, energy, chemical and other industries. It has the characteristics of reliable structure, low energy consumption, high screening efficiency, low vibration and noise, durability, convenient maintenance, safe operation, etc. Our customers have feedback that they do not know how to choose the appropriate vibrating screen suppliers. The editor will introduce the selection method of vibrating screen for you.

1. Consider the type of material

When choosing a vibrating screen equipment factory, the first thing to consider is the type of material. In production, there are various types of materials, and their hardness and properties are quite different. Common materials such as ore, sand and powder. When users choose circular vibrating screen manufacturer, they must make a reasonable choice according to the actual production situation, so as to take advantage of the vibrating screen. For some special materials such as viscous, strong adsorption, and easy agglomeration, circular vibrating screen machines cannot be used.

2. Consider actual production needs

The function of the vibrating screen is to remove the impurities contained in the materials, improve the quality of the materials, and screen out qualified materials for further processing and use. Therefore, when we choose vibrating screen device, we must conduct a comprehensive analysis based on our own production requirements, screening grades, screening requirements, and filtration levels. The greater the power of the vibrating screen, the higher the throughput, and we must communicate more with the merchants. Choose the right equipment.

3. Consider the size of production output

3. Consider the size of production output

When choosing a vibrating screen facility, we must also consider the production capacity of the production line. There are many types of vibrating screens, and the production capacity of different types of vibrating screens is also quite different. Therefore, before we choose to buy a circular vibrating screen appliance, we must understand the production capacity of the production line before purchasing. Pay attention to the sieving accuracy and screen specifications of the vibrating screen when purchasing.

4. Consider the material of the vibrating screen

4. Consider the material of the vibrating screen

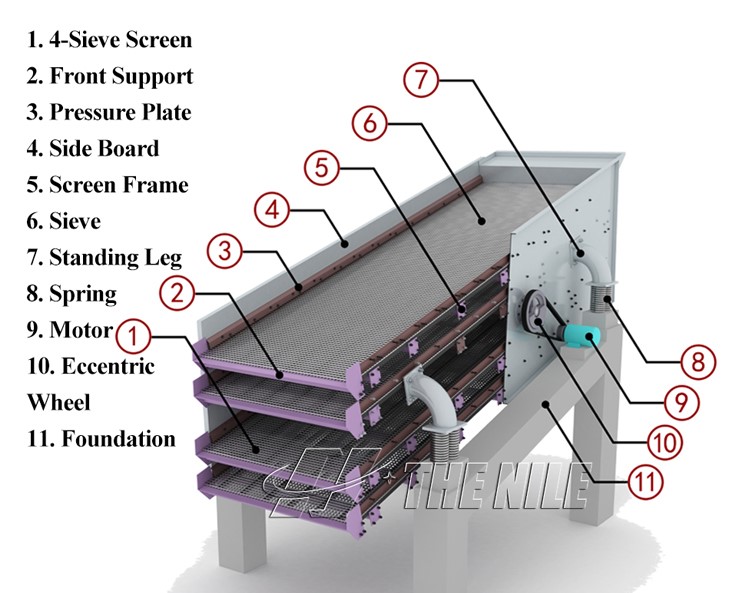

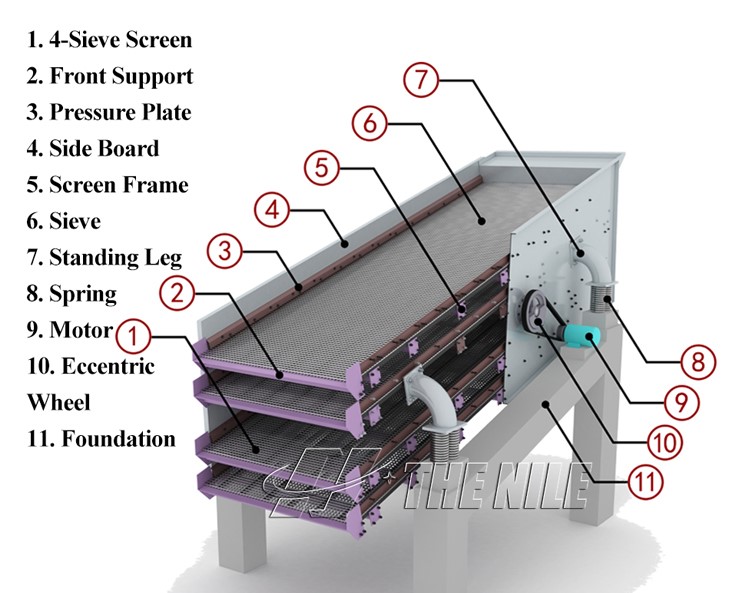

First of all, we must understand that the accessories of the vibrating screen machinery are mainly composed of a circular vibrating screen, which mainly consists of a screen box, a screen, a vibrator, a damping spring device, a chassis, a suspension (or support) device, and a motor. Secondly, we must understand the selection of materials, because the selection of materials is related to the quality and whether the screening efficiency and accuracy can meet the requirements in the subsequent use. There are two types of materials, one is that the whole machine is made of stainless steel, and the other is that the parts contacting the material are made of stainless steel. Both have the characteristics of wear resistance, long life and corrosion resistance. High materials have higher efficiency but higher prices. Generally, materials have lower efficiency but moderate prices. We can choose according to our own needs.

The above gives you a detailed introduction to how to purchase circular vibrating screens. Nile Machinery has rich experience and strong technical strength, and can provide users with free consultation, model selection, quotation, design, and production line services. Users who want to know more about vibrating screen equipment can consult online customer service for free.

1. Consider the type of material

When choosing a vibrating screen equipment factory, the first thing to consider is the type of material. In production, there are various types of materials, and their hardness and properties are quite different. Common materials such as ore, sand and powder. When users choose circular vibrating screen manufacturer, they must make a reasonable choice according to the actual production situation, so as to take advantage of the vibrating screen. For some special materials such as viscous, strong adsorption, and easy agglomeration, circular vibrating screen machines cannot be used.

2. Consider actual production needs

The function of the vibrating screen is to remove the impurities contained in the materials, improve the quality of the materials, and screen out qualified materials for further processing and use. Therefore, when we choose vibrating screen device, we must conduct a comprehensive analysis based on our own production requirements, screening grades, screening requirements, and filtration levels. The greater the power of the vibrating screen, the higher the throughput, and we must communicate more with the merchants. Choose the right equipment.

When choosing a vibrating screen facility, we must also consider the production capacity of the production line. There are many types of vibrating screens, and the production capacity of different types of vibrating screens is also quite different. Therefore, before we choose to buy a circular vibrating screen appliance, we must understand the production capacity of the production line before purchasing. Pay attention to the sieving accuracy and screen specifications of the vibrating screen when purchasing.

First of all, we must understand that the accessories of the vibrating screen machinery are mainly composed of a circular vibrating screen, which mainly consists of a screen box, a screen, a vibrator, a damping spring device, a chassis, a suspension (or support) device, and a motor. Secondly, we must understand the selection of materials, because the selection of materials is related to the quality and whether the screening efficiency and accuracy can meet the requirements in the subsequent use. There are two types of materials, one is that the whole machine is made of stainless steel, and the other is that the parts contacting the material are made of stainless steel. Both have the characteristics of wear resistance, long life and corrosion resistance. High materials have higher efficiency but higher prices. Generally, materials have lower efficiency but moderate prices. We can choose according to our own needs.

The above gives you a detailed introduction to how to purchase circular vibrating screens. Nile Machinery has rich experience and strong technical strength, and can provide users with free consultation, model selection, quotation, design, and production line services. Users who want to know more about vibrating screen equipment can consult online customer service for free.

- Recommended News

- Detailed introduction of Wet pan mill.

- Spiral classifier

- Mobile Trommel Gold Wash Plant

- Discover The Nile's High Performance Wet Pan Mill: Revolutionizing Gold Material Processing

- A Multi-Purpose Grinding Equipment: Wet Pan Mill

- Best Choice for Placer Gold Processing: The Trommel Gold Washer

- Jig Machine in Gravity Concentration for Particles Separation

- A New Type Environment Protection Equipment Fine Sand Recycling Machine

- Hammer Crusher VS Impact Crusher: Technical Comparison and Selection Guide

- Ship directly from Our Factory In Zhengzhou

Recommended Products

More

More